HIK COMPETENCY

Our COMPETENCYfor your success

Manufacturing engineering skills & capacities, a pronounced quality awareness and the best possible lean logistic processes: in our three areas of expertise, we work daily to provide our customers with the optimal support to complete their jobs and thus increase their success in an evermore demanding market environment.

Our three pillars increase your success in the market:

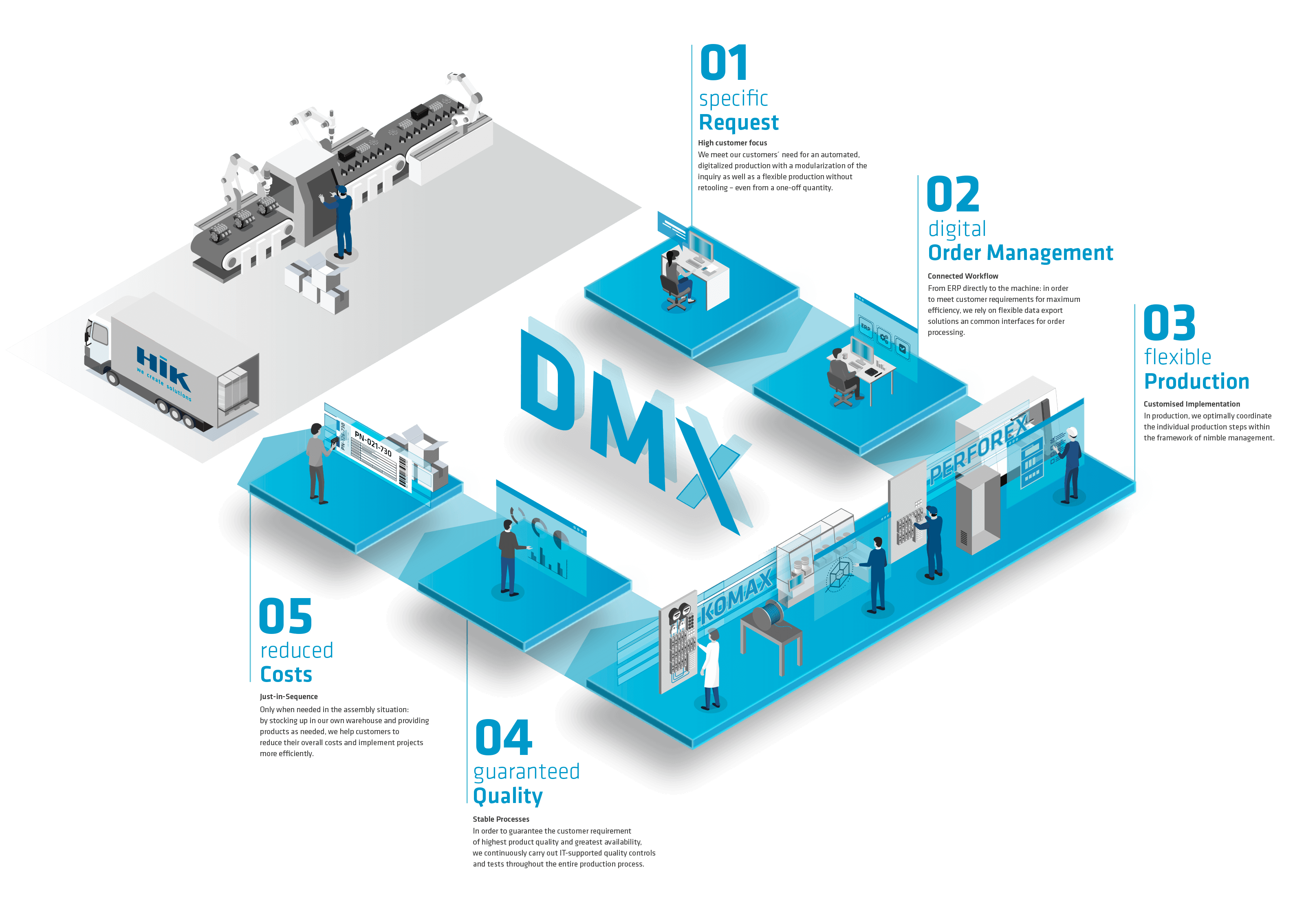

DIGITAL

Continuous digitalisation of all processes throughout the added value chain

MANUFACTURING

Comprehensive automation in a state-of-the-art machine shop

EXPERIENCE

Experienced professionals for industries, applications and manufacturing technologies

Get to know the HIK Digital Manufacturing Experience

using the example of our

digitised wire processing construction.

More about

HIKwire

Your advantages at a glance:

Significant time saving

Reduced workload

Greater process safety

High efficiency

Consistent quality

Comprehensive solution

HIK Skills & Capabilities

With established Know-howleading to perfect solutions

For more than 30 years the right mix of technical capabilities and professional know-how has enabled us to provide our customers with exactly the solution they need to achieve their business goals.

Component consultation

Component consultation

Technical advice

and optimisation applications

from a single source.

We offer our customers comprehensive consulting services in various areas such as application optimisation, availability of raw materials or calculation support. The aim of our consulting services is to shorten development times, simplify production or avoid later additional costs in the roll-out by early detection of faults.

Welding technology

Welding technology

Welding solutions

for greater product and

plant safety.

In conjuntion with our technology partner, we use state-of-the-art connection methods such as resistance welding, in which electrically conductive materials are joined irreversibly and with the highest precision. This reduces contact transfer resistances and increases your product and plant safety.

Training and Development

Training and Development

Developing expertise

through internal & external

training.

In order to be able to advise our customers in a wide range of industries taking into account the latest technologies and to develop the solution they really need for their work, we invest a lot in the training and further education of our employees. In addition to the seminars at the HIK Academy, our employees also regularly take advantage of external training opportunities

Labeling techniques

Labeling techniques

Labeling solutions

for individual

requirements.

We implement your individual requirements in the field of marking exactly: from laser marking of enclosure surfaces and cable surfaces, to label and marking solutions.

Simultaneous Engineering

Simultaneous Engineering

Optimum coordination

of all process-relevant

fields and techniques.

In the planning phase, we work closely with all departments involved and develop the appropriate solution using E-CAD and M-CAD. We also advise on the choice of the appropriate production technology. The focus of our simultaneous engineering is a balanced relationship between feasibility and efficiency.

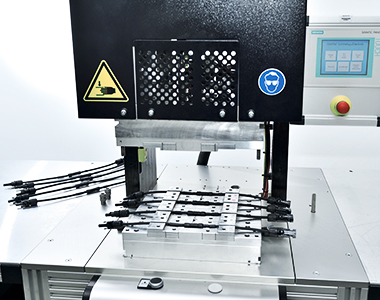

Injection moulding

Injection moulding

Versatile potting solutions

for different

customer requirements.

We react flexibly to the requirements of our customers with, for example, different casting processes or different casting systems. Depending on customer requirements and application, we use low-pressure hotmelt including EPDM and TPE in this area.

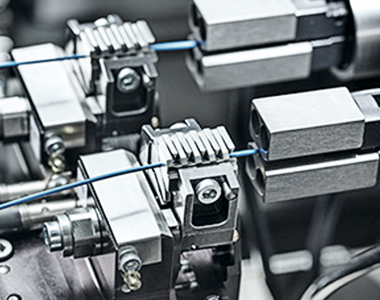

Crimping techniques

Crimping techniques

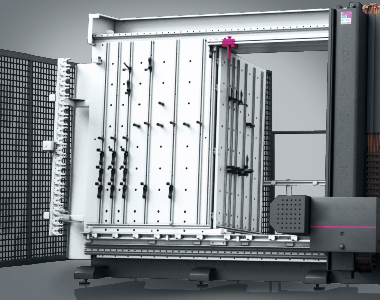

Modern Maschines

for increased automation

and maximum productivity.

From manual processing to fully automated and digital ladder set production: Our state-of-the-art machine shop, equipped with systems from the technology & market leader Komax, among others, enables economical automation processes with high productivity as well as reliable processing of the highest quality.

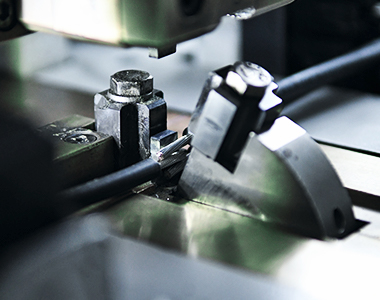

Cutting technology

Cutting technology

Comprehensive abilities

for precise

cabling solutions.

From the fully automated stripping and crimping line to multi-stage processing of multicore cables with cable shielding: we draw on a wide range of possibilities to respond optimally to your needs and deliver results accurate to the millimeter.

Enclosure machining

Enclosure machining

Without deviation

from design

to the final assembly.

Thanks to our highly flexible drilling and milling plant, we ensure that required housing parts can be moved from the design stage to final assembly without any loss of time. In this way, we can guarantee the shortest possible lead times and a consistently high level of processing quality.

HIK Quality

With impeccable quality to total satisfaction

We supply our customers with products that guarantee perfect quality even very complex ones. To keep this promise, HIK continuously optimises its business processes. Thanks to our many years of expertise in cable assembly, control cabinet construction as well as development and production of mechatronic solutions, our promise of quality applies not only to individual products, but also to the entire value-added process.

End-of-Line Test

Process quality

Sampling

Consultation

HIK Academy

Obsolescence management

Tests during development

HIK Logistic services

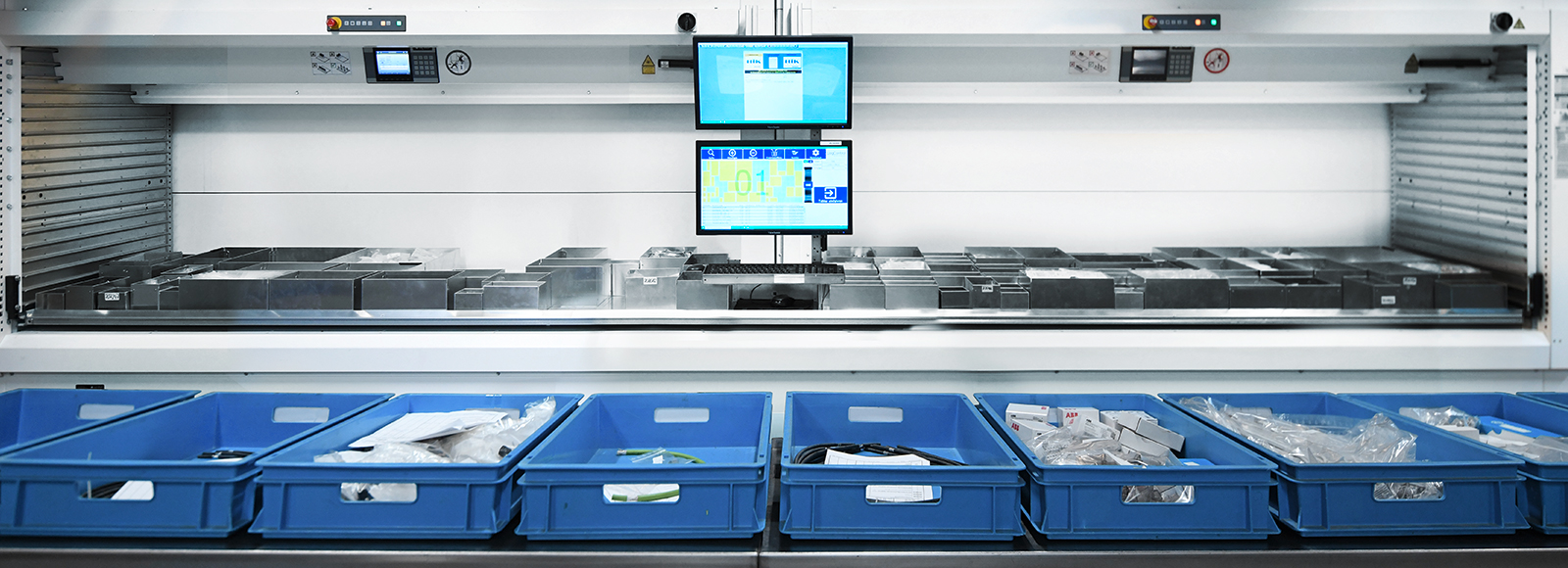

With a comprehensive conceptto maximum economic efficiency

Reduce process costs, reduce the number of suppliers, simplify ordering processes:

we regard logistics as a comprehensive process and use the various aspects of logistics to optimise the overall cost-effectiveness of our customer solutions.

VMI/Kanban

Consignment warehouse

C-Parts Management

Spare parts management

Fulfillment

- Goods receiving department

- Order picking

- Packing & Shipping

- Export & customs declarations

- Returns management

Packaging

- Container management

- UL marking

- Multiple use packaging concept

- Printing in one or more languages

- Customs clearance

contact

HIK SupportWe are looking forward to your message.

If you have any questions about our products or services, please contact us by phone, email or use our contact form: In any case, we will get back to you as soon as possible.